hardness tester brinell|brinell hardness test calculator : exporter Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .

WEB22 de fev. de 2024 · A ANIMALE é uma das maiores marcas do mundo no mercado de moda feminina. A empresa de Cláudia e Roberto Jatahy nasceu em 1991 como um sonho que iniciou na forma em uma loja no Leblon, Rio de Janeiro. Hoje, a ANIMALE se destaca entre as mais importantes grifes de moda do Brasil, com mais de 80 lojas em todo o .

{plog:ftitle_list}

Alessandra Negriniestampou a capa da revista masculina em abril de 2000. Sua edição vendeu aproximadamente 538 mil exemplares. Na . Ver mais

A basic Brinell hardness tester with semi-automatic operation. NB3010 is a cost-effective Brinell tester using deadweights with a pneumatic load system to apply and remove the loads. .King Portable Brinell Hardness Testers are the most reliable, easy to use and affordable portable Brinell testers that are certified and calibrated per ASTM E-10 standards and the ONLY portable Brinell testers on the market that are .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information .BRINELL HARDNESS TESTERS Brinell is used for hardness testing larger samples with a coarse or inhomogeneous grain structure. The indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the .

Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested. The diameter of the indentation is then .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .The Newage KB Series is a popular, manually-controlled Brinell hardness tester that meets ASTM E-110. This lightweight, portable tester is ideal for virtually any size or shape of metal specimen. The Newage KB Series is a popular, manually-controlled Brinell hardness tester that meets ASTM E-110.

Brinell Hardness Tester is a rapid and accurate method to determine hardness value with ASTM E-10 compliance. Applying loads of up to 3.000 kgf, the Brinell test is ideal for castings and forgings. Skip to main content [email protected] 1-877-884-8378 .The easiest and most portable hardness tester on the market. Use it in tight spots, right side up, upside down, or sideways! King Portable Brinell Metal Hardness Testers are the most reliable, easy to use, and affordable portable Brinell testers available and the ONLY portable Brinell testers on the market that are Directly Verifiable.The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. The diameter of the resulting permanent impression in the tested metal is measured and the Brinell Hardness .

lee brinell hardness tester chart

1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .The Wilson BH3000 Brinell Hardness Tester, with a robust 3000 kgf capacity, covers a wide range of loads from 62.5 kgf to 3000 kgf. Engineered for durability in harsh environments, it features rugged construction, heavy-duty clamping, and protection. The closed-loop system ensures quick and precise test results, while integrated hardness .The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.

The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to deformation of the carbide ball. The flattening of the ball results in a larger indentation diameter and thus .A complete range of hardness testers and hardness testing machines for Brinell, Rockwell, Knoop and Vickers hardness testing, as well as consumables and accessories – all designed to improve the accuracy and efficiency of your materialographic .

orion af8 volumetric karl fischer titrator store

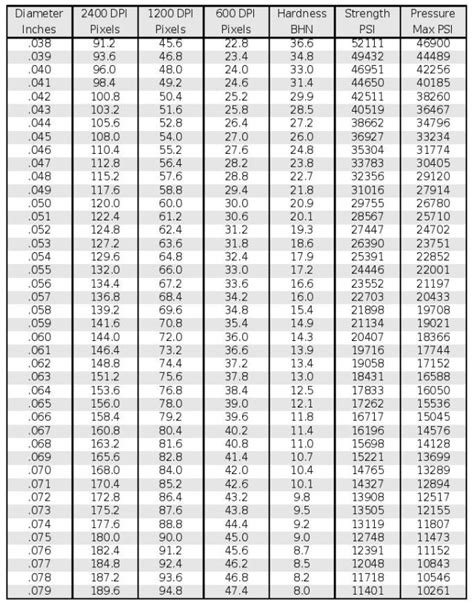

The Pin Brinell from Newage is the standard for economical Brinell hardness measurement. This simple-to-use and inexpensive tester can be used across the entire Brinell range (HB100 to HB700). The Pin Brinell is compact and this .The Newage Pin Brinell is the de-facto standard for economical Brinell hardness measurement. This simple-to-use and inexpensive tester can be used across the entire Brinell range (HB100 to HB700).These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .

The KB Series hardness tester applies up to 3000 kg load on a 10mm ball, making a visible indentation that is read using a Brinell scope or our B.O.S.S. system.The calibrated accuracy is better than 0.5% of the applied load.Portable Brinell Hardness Tester KH180,can be Freely Converted to All Hardness Systems (HL, HB, HRB, HRC, HRA, HV, HS) Without Calculation. 9.00 $ 239. 00. List: 9.00 9.00. FREE delivery Wed, Aug 28 . Only 16 left in stock - order soon. Add to cart-Remove. The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number. Brinell hardness of some materials. Material. Brinell Hardness. Copper. 35 HB. Aluminum (pure) 15 HB. AW-6060 aluminum.

The Brinell hardness test is defined in ASTM E10 is used to calculate Brinell hardness of the metal. It is used on the metal having a rough surface and harsh texture. The Brinell hardness test is used to measure the hardness of light metals like lead and tin, also hard metals like steel and iron.

The Brinell hardness test method often presents some challenges for users. Poor operating conditions, inexperienced users, tedious high-volume testing and demanding applications contribute to reduce accuracy and repeatability. Newage Brinell testers can meet these challenges and help ensure accurate, consistent results. Starrett Hardness Testers indicate the hardness of a material, usually by measuring the effect on its surface of a localized penetration by a standardized rounded or pointed indenter of diamond, carbide, or hard steel. . With a range of models available, including Rockwell, Brinell, and Vickers testers, Starrett offers the perfect tool for .The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .Depending on the model, the hardness tester covers load ranges from 0.3-250 kg or 3-3,000 kg. The macro hardness tester covers optical methods and differential-depth methods for your hardness testing applications. This includes Vickers, Brinell, Knoop or Rockwell.

Optical Pocket Scope - Brinell Hardness Testers B.O.S.S. Optical Scope - Brinell Hardness Testers The B.O.S.S. from Newage is a Brinell optical scanning system that includes a high resolution video scanning head and imaging software that ensures a fast, accurate, and consistent reading of all Brinell impressions. .

brinell hardness testing machine diagram

sodium tartrate dihydrate water standard for volumetric karl fischer titration store

v20 volumetric karl fischer titrator store

Loli/Appearance +18. a collection by SSLucky · last updated 2024-01-21 06:15:39. Follow SSLucky Following SSLucky Unfollow SSLucky. Agent17 (18+ Adult Game) NSFW .

hardness tester brinell|brinell hardness test calculator